-

Semi electric aluminum alloy lifting platform

-

All electric lifting platform

-

Semi electric scissor type lifting platform

-

Tank truck sampling ladder

-

Manual lifting platform

-

Warehouse reclaimer

-

Vehicle mounted lifting platform

-

Inflatable wheel lifting platform

-

Flip frame lifting platform

-

Explosion proof lifting platform

-

Extension countertop lifting platform

-

Insulated guardrail lifting platform

-

Stainless steel lifting platform

-

Fixed scissor lift platform

-

Unloading platform

Home

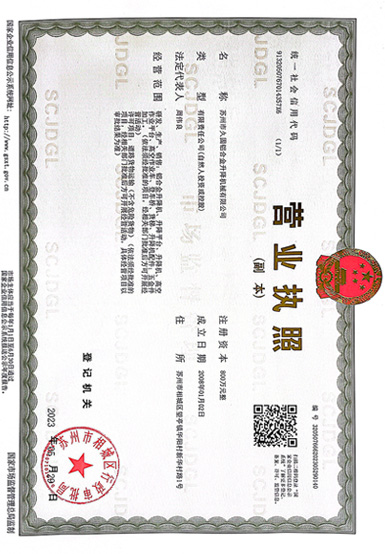

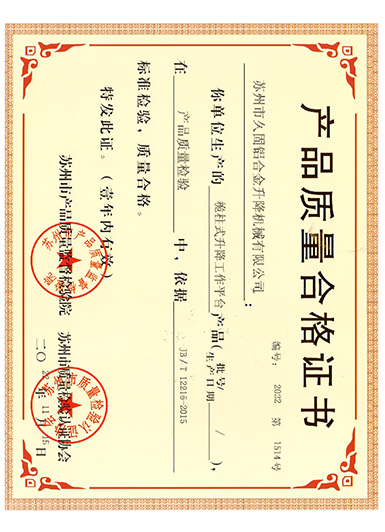

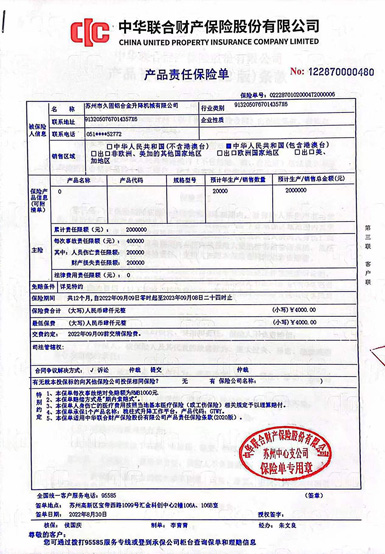

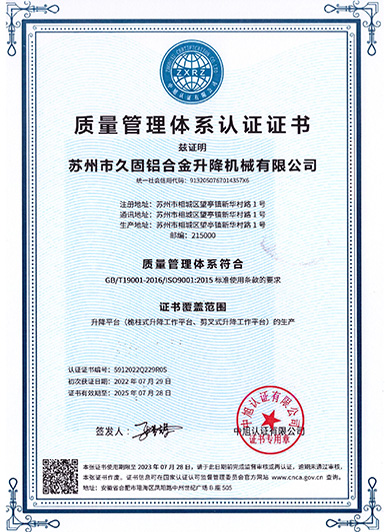

About Us

-

Products

Semi electric aluminum alloy lifting platform

All electric lifting platform

Semi electric scissor type lifting platform

Tank truck sampling ladder

Manual lifting platform

Warehouse reclaimer

Vehicle mounted lifting platform

Inflatable wheel lifting platform

Flip frame lifting platform

Explosion proof lifting platform

Extension countertop lifting platform

Insulated guardrail lifting platform

Stainless steel lifting platform

Fixed scissor lift platform

Unloading platform

Cases

-

News

Contact Us